Size: large

Type: image

Oslo’s water and sewerage agency (VAV) started to use biofuels instead of diesel in construction projects to reduce greenhouse gas emissions in 2017. Back then, access to green alternatives and renewable technology for construction machinery and large vehicles were limited. But now things have changed!

In 2019, the City of Oslo introduced requirements for fossil-free construction and mass transport. At the same time, zero-emission alternatives and biogas were rewarded in the procurements, starting the green evolution and results we see today. In just two years we have seen a shift in our contracts, from no electrical machines to only electrical machines in some cases!

How did we do it?

Rewarding contractors who use electrical machines

Contractors compete to win on different levels when we announce a potential contract. They are evaluated on price level, the quality of their work, and environmental impact.

The environmental aspect has become increasingly important since October 2019. The contractors focus on using green alternatives stands for 30 precent of our decision, while the importance of price have decreased. This makes it easier for the contractors to highlight the investments and risks they are taking to reduce emissions, without lowering the chances to win the contract.

In the process we give different scores to different technologies, which to some extent corresponds with the additional cost of the investments. Zero-emission such as electricity and hydrogen get the highest score, while biogas gets half of it. Fossil-free liquid biofuel is the minimum requirement to participate and does not get a score.

For the mass transport in Oslo, the goal was to get at 50 percent fossil-free by 2020 and 60 percent by 2021. The reason why we are not able to get to 100 percent right away is that we still have old contracts that were entered before the new environmental requirements in 2019.

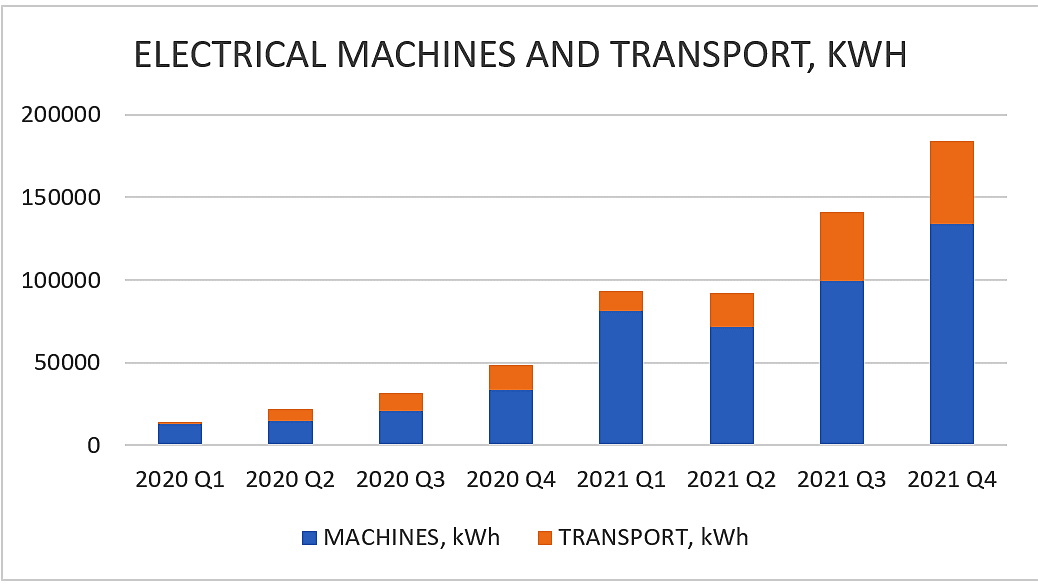

However, the transition to fossil-free alternatives is moving fast. We are receiving an increasing amount of offers with zero-emission implementation. We see a rapid increase in the use of zero-emission solutions in many of our rehabilitation projects. Each kWh used corresponds to potential diesel use and emissions (see diagram below).

As a result of better planning, we also save energy on electrification and increased reuse of masses. That is the cherry on top!

The diagram shows reported fuel consumption in projects for the rehabilitation of the water and sewage network in Oslo.

Communication and trust

We have used several tools to get to where we are today. One of them is how we communicate with the industry. To get contractors and companies on our side we have been clear about our goals, the path we have chosen and that the risk they potentially are taking is lower than they might think. Just a year ago we were constantly getting calls from companies unsure about the risks, hesitating to make a move and to invest in green technology. Now we do not get calls like that anymore. Contractors are buying both electric machines and trucks in large numbers.

We are also beginning to see the transition from electrical prototypes to large scale production.

Espen Hauge is a section leader in the the Agency for Water and Sewerage Works in Oslo

Just the beginning

The environmental requirements are a priority for us, and we make sure the contractors deliver what they have offered in the contract. They self-report, send us documentation, we have follow-up meetings at the construction site, as well as random checks.

As expected, some problems have emerged. Charging is the most common, but most projects are running smoothly. Entrepreneurs who use zero-emission solutions report more benefits than difficulties, even though it takes a lot of planning.

Our score system lets the market find the right solutions. The strategy works because the contractors know best what works for them and how they can solve each project. It creates a space for new thinking, innovation, and focus on environmentally friendly solutions.